It is essential to provide a safe working environment for operators, especially when pneumatic tools and compressed air are used.

If there is a fault in the air network and the hose is not clamped properly, the whiplash effect can be devastating. Failure to comply with good practices may result in injuries, resulting production stoppages and decreased production efficiency.

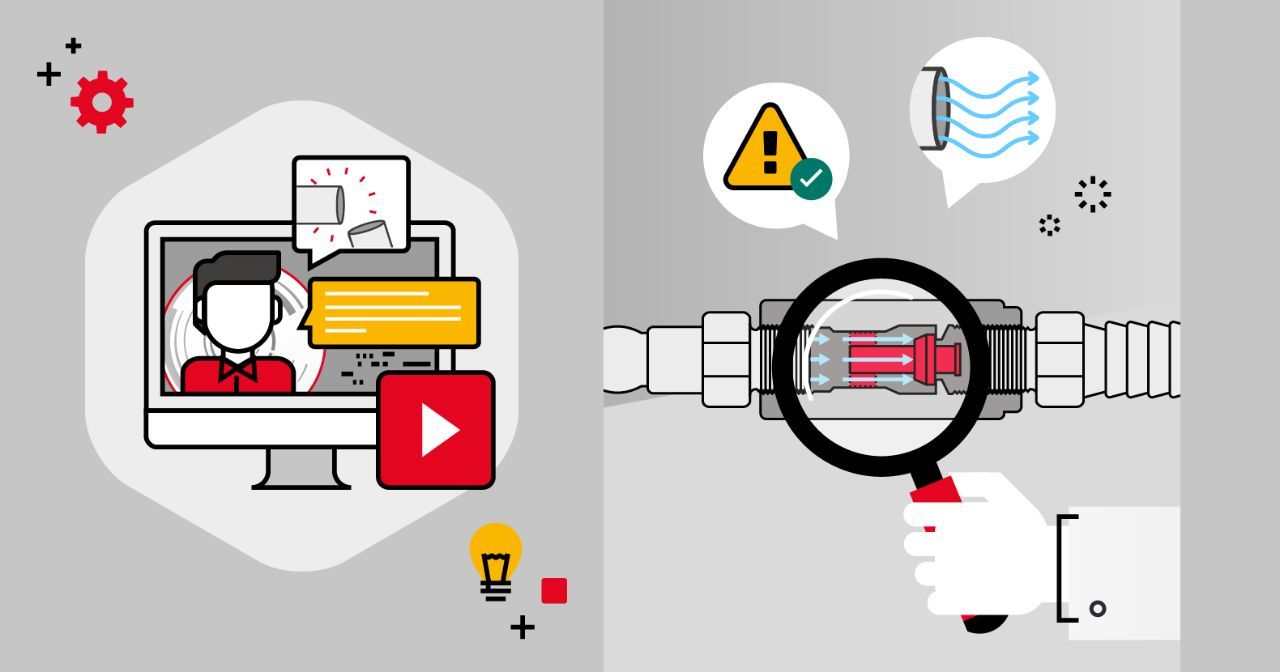

In this video, our Accessory Product Manager, Annabelle Bray, shows how to install an air fuse valve on an air line assembly in seconds and offers advice to both increase workplace safety and protect workers from potential hose whip effects.

Installing an air fuse valve in your air line assembly will protect you from hose whip effects.

Son Yazılar

- Four key factors to ensure optimum performance of your pneumatic tool

- Why is tool calibration important?

- Pneumatic torque adjustable impact driver nuts and bolts: Preventing overtightening

- Maintenance of air line and hammer mechanism

- Safety precautions during metal processing

- What is Conditioner (FRL)?

- Preventing objects from falling when working at height

- The secret to efficient industrial drilling operations

- Which tool is best for you? Pneumatic or Electric?

- Why does the pneumatic grinder motor rotate very slowly?