Have you noticed that your pneumatic tool is underpowered or not working as expected? This may be due to your air line accessories and/or connection rather than the tool itself. It is important to quickly check your air line installation. This is a simple job that only takes a few minutes.

It's easy: From the filter, regulator and lubricator to the FRL tool inlet, each accessory must be selected with the following four basic tool values in mind:

1. Input size

It is the size of the air inlet of the tool. This value helps you choose the correct connector size.

2. Entry type

It is the type of thread on the air inlet of the tool. There are three main types of pneumatic tool entry threads:

- NPT (National Pipe Thread), mostly used in America,

- PT (Pipe Thread), mostly used in Asia,

- BSP (British Standard Pipe) is mostly used in Europe.

Safety tip: Never mix thread types as this may lead to incorrect connections or air leaks.

3. Air compression as dynamic pressure

The volume of compressed air required for proper and efficient operation of the tool. This value is given in cubic feet per meter (cfm) or liters per second per minute (l/s or l/m).

4. Recommended hose diameter

Although this is not classified as a typical tool value, tool manufacturers often recommend the correct hose diameter value for tools to perform best. The value is stated in millimeters (mm) and/or inches ("").

Where can I find this information?

Refer to the manufacturer's online recommendations, the tool's printed catalog or user manual.

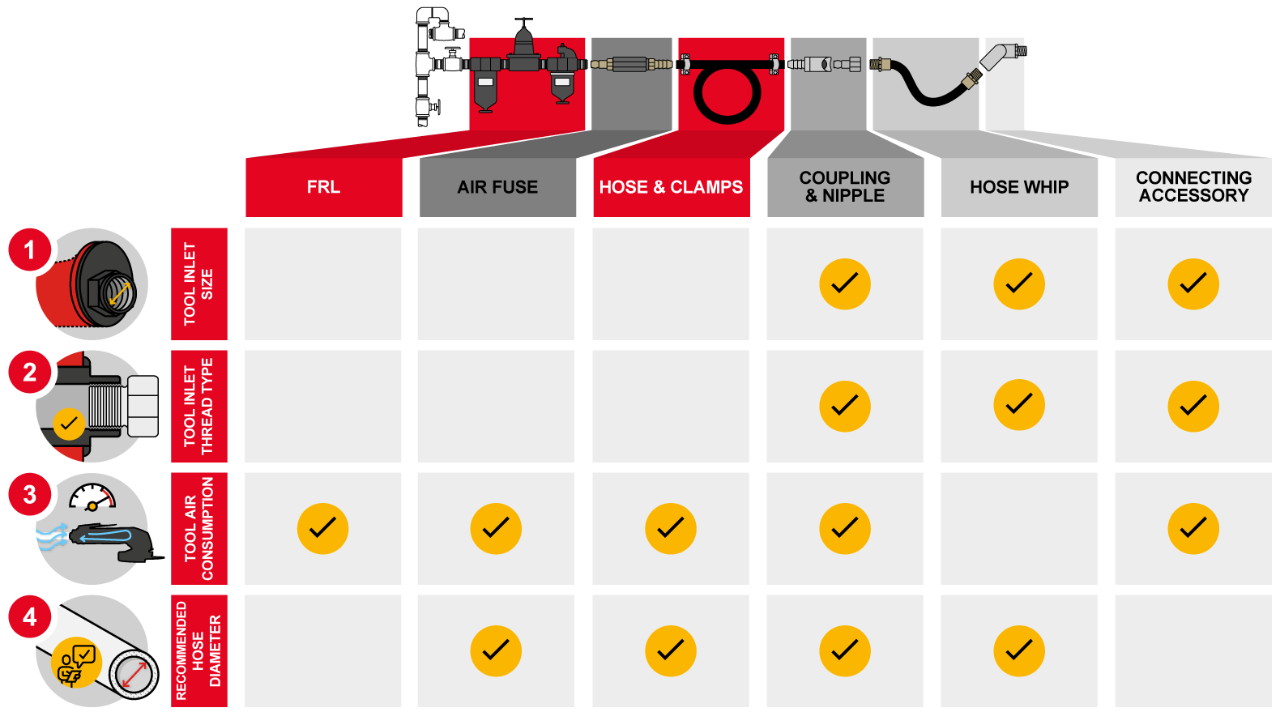

What are the important factors for each type of accessory?

4 basics in choosing air line accessories vehicle value must be taken into consideration

4 basics in choosing air line accessories vehicle value must be taken into consideration

- Why is tool calibration important?

- Pneumatic torque adjustable impact driver nuts and bolts: Preventing overtightening

- Maintenance of air line and hammer mechanism

- Safety precautions during metal processing

- What is Conditioner (FRL)?

- Preventing objects from falling when working at height

- The secret to efficient industrial drilling operations

- Which tool is best for you? Pneumatic or Electric?

- Why does the pneumatic grinder motor rotate very slowly?

- ATEX, NEC, DSEAR… what is it and how can it help you?