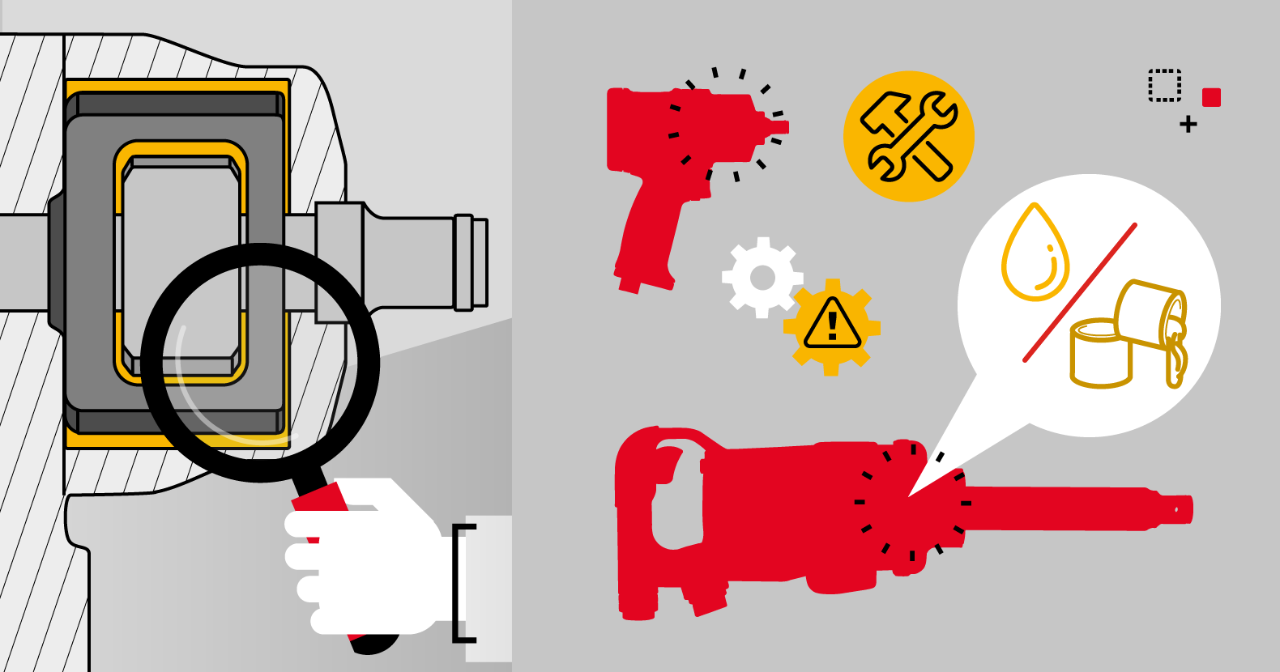

Increase the durability and life of your impact wrench by lubricating the air line and hammer mechanism

Is your pneumatic impact wrench starting to become unreliable, not working as it should, or stopping suddenly? One of the most common causes of durability and premature tool failure is inadequate lubrication not only in the air motor but also in the hammer mechanism.

It is well known that regular maintenance is essential to keep your tool performing at its best. Just like you keep the oil level in your car full, it's important to check the oil and grease in your tool regularly. A little maintenance may be enough to increase its durability and life.

In this blog we'll look at two different areas of lubrication and explain how you can properly maintain your impact wrench so it continues to deliver excellent performance over a long lifespan. We'll also discuss how often you should lubricate your air tools and what type of oil you should use to work as productively as possible

Which parts of an impact wrench need to be lubricated?

Two parts of the drill must be considered when it comes to lubrication:

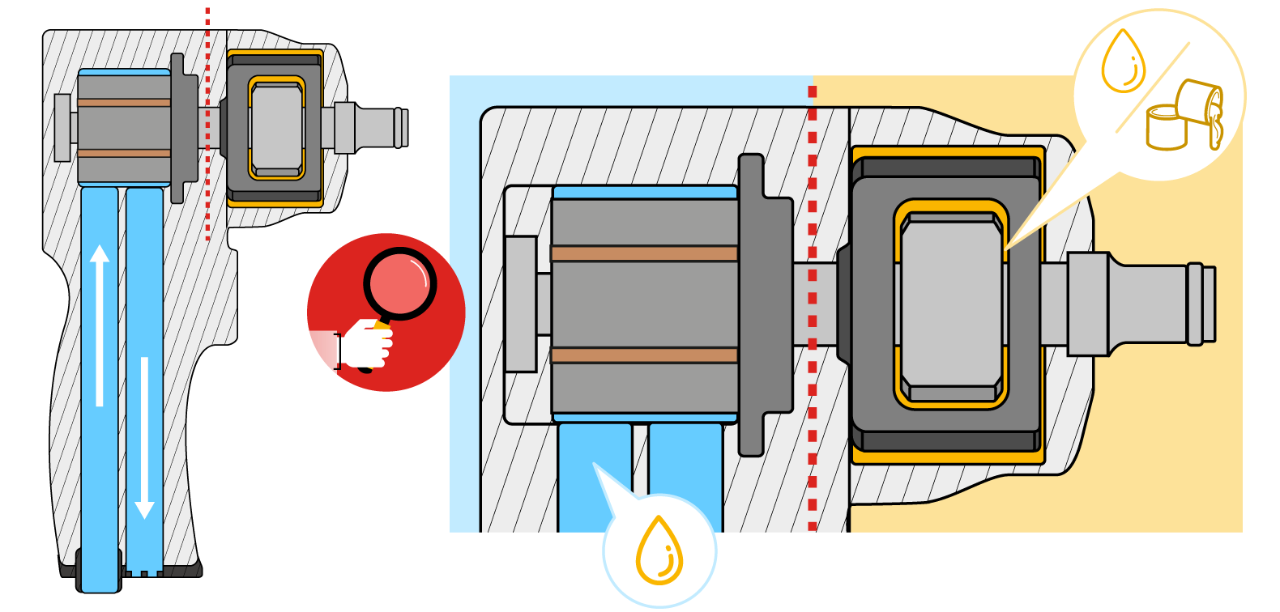

You may know that the engine needs to be lubricated regularly, but did you know that the hammer mechanism also needs to be lubricated? The two systems are independent of each other and must therefore be lubricated separately. The Air Motor is lubricated by the Conditioner (FRL) or a specific air line lubricant that you add directly to the air inlet on the tool. The hammer mechanism is lubricated in two ways, depending on the system used by the tool. These are:

- Grease hammer mechanism

- Oil chamber hammer mechanism

Understanding the two types of lubrication systems of the hammer mechanism

Lubrication of the hammer mechanism is of great importance to minimize friction between the impact contact points of the anvil and the hammer, ensuring that the key continues to operate in perfect condition. Now let's look at these two systems in more detail:

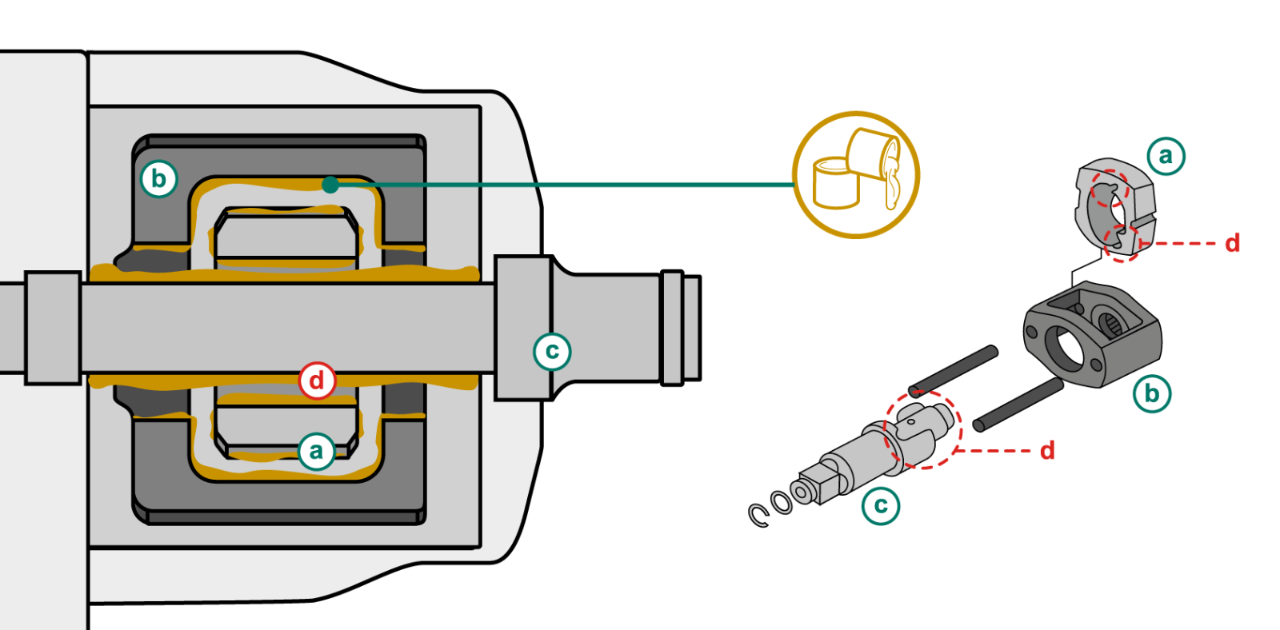

1. Grease system:

In this system, grease is applied only to the contact points between the anvil and hammer to prevent friction between them.

In an impact boring mechanism with a grease system, grease must be replenished regularly.

However, the grease (inertia principles) does not remain in this critical area as it moves from the contact points to the outside of the hammer over time. As a result, friction and heat increase, and the tool eventually stops working. Grease must be replenished regularly.

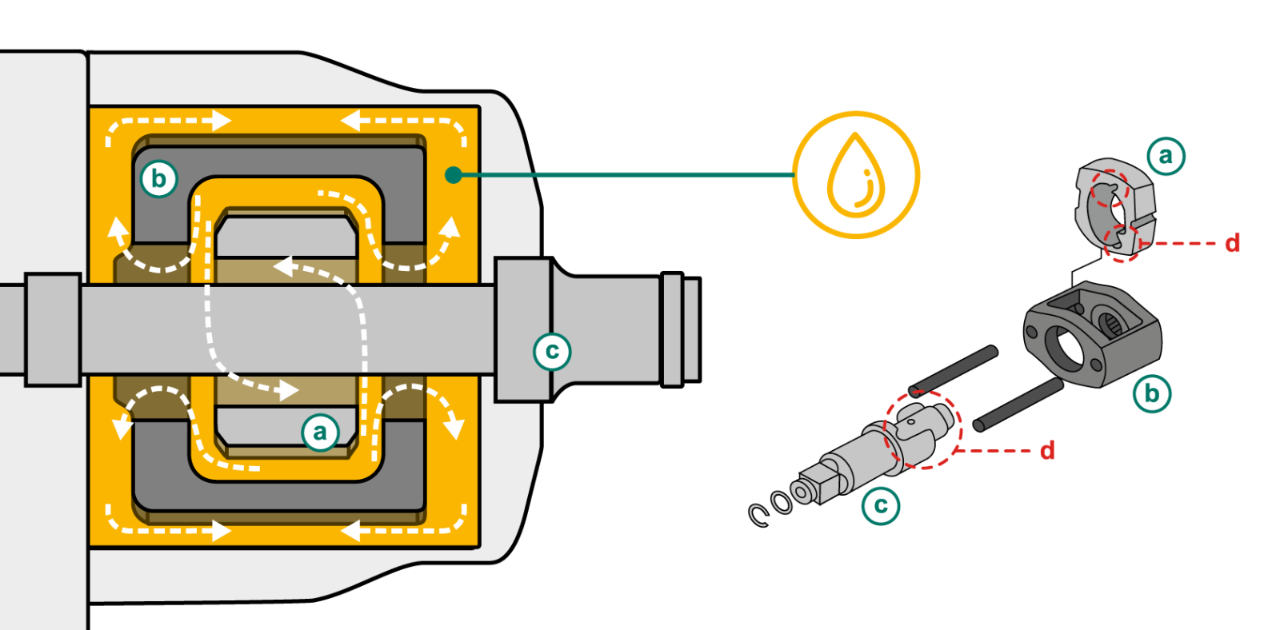

2. Oil chamber system:

Oil lubricated hammer mechanism

In a tool that uses the oil reservoir system, the entire front of the impact wrench is immersed in oil. There is no question whether oil is present or not, because oil surrounds the entire system

An advantage of this is that the tool requires less maintenance because the contact points are always lubricated. Maintenance can be more difficult, but with the right tips and advice, as outlined below, it becomes very easy to do.

How to properly lubricate the hammer mechanism of an impact wrench?

1. Grease system:

To properly lubricate the hammer mechanism, we recommend turning on the tool and carefully adding grease with your hands or a brush to critical contact points, namely the anvil (the area in contact with the hammer) and the interior area of the hammer.

Most pneumatic tools have more than one grease connection and it is sometimes possible to add grease through these holes if it is not possible to lubricate the impact mechanism as described above. If you're not sure where these are, check your manual or ask your service provider. Remember to remove old grease before adding new!

2. Oil chamber system:

To change the oil, you must carefully open the tool, drain and properly dispose of the used oil, and then replace it with new oil.

You must only use oil suitable for impact systems, such as SAE30 type oil.

Note: This oil is different from the oil used in air lubrication.

- Four key factors to ensure optimum performance of your pneumatic tool

- Why is tool calibration important?

- Pneumatic torque adjustable impact driver nuts and bolts: Preventing overtightening

- Safety precautions during metal processing

- What is Conditioner (FRL)?

- Preventing objects from falling when working at height

- The secret to efficient industrial drilling operations

- Which tool is best for you? Pneumatic or Electric?

- Why does the pneumatic grinder motor rotate very slowly?

- ATEX, NEC, DSEAR… what is it and how can it help you?