Are you having trouble drilling some materials? Are the holes you drill messy and damaged? Do you want to achieve more efficiency and improve the quality of the holes you drill?

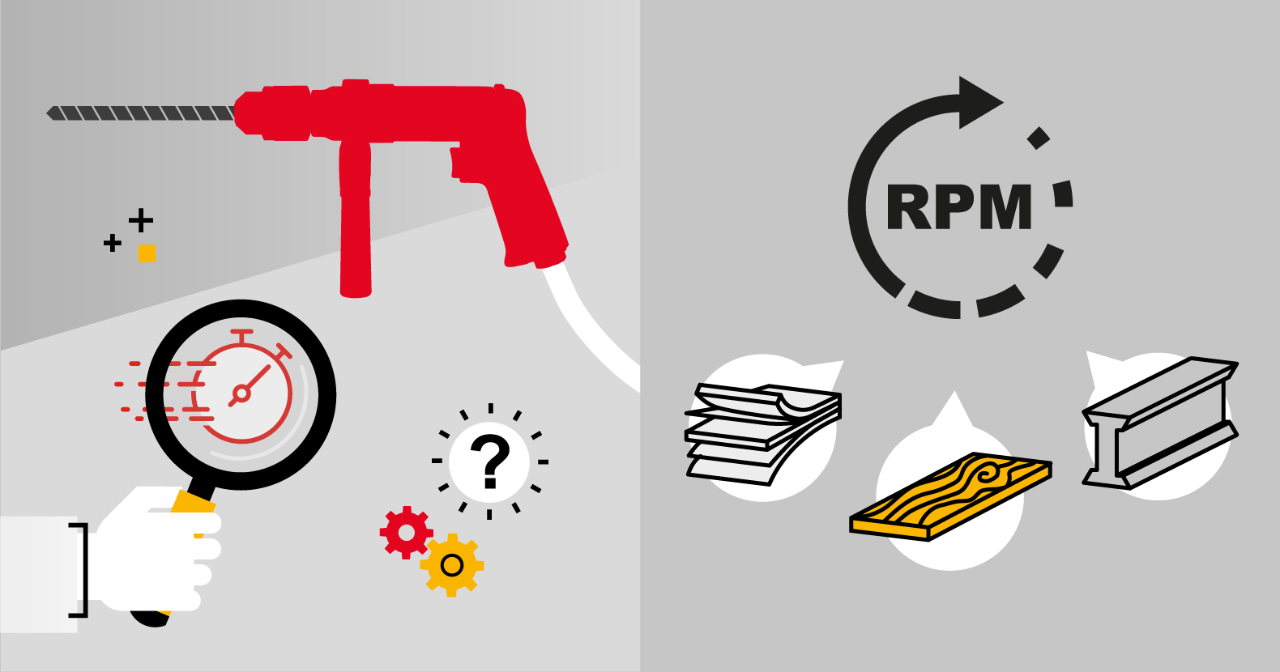

It is possible to drill almost any material when you have the right tool, drill bit and speed. Whether you are drilling composite material or hardened steel for an oil and gas or metalworking application, it is the speed of the drill that has the greatest impact on quality and productivity.

Below you can find important tips that will help you drill more effectively and safely.

The most crucial point of effective drilling is speed

First, identify the material you are drilling.

Soft materials: Soft materials such as wood or composite are generally considered easy to drill and not much thought is given to the drilling tool, especially if the hole to be drilled does not need to be of very high quality. However, if the hole must be drilled with precision, speed is vital. With the right speed and drill bit, the tool can easily drill a clean, complete hole.

Hard materials: Hard materials such as hardened steel, alloy steel or cast iron are more difficult to drill than soft materials. For drilling hard materials, a tool with the right power, torque and speed is a must. The success factors here are lower speed and lubrication!

You can see the effect of drill speed on aluminum sheet in our short video here: